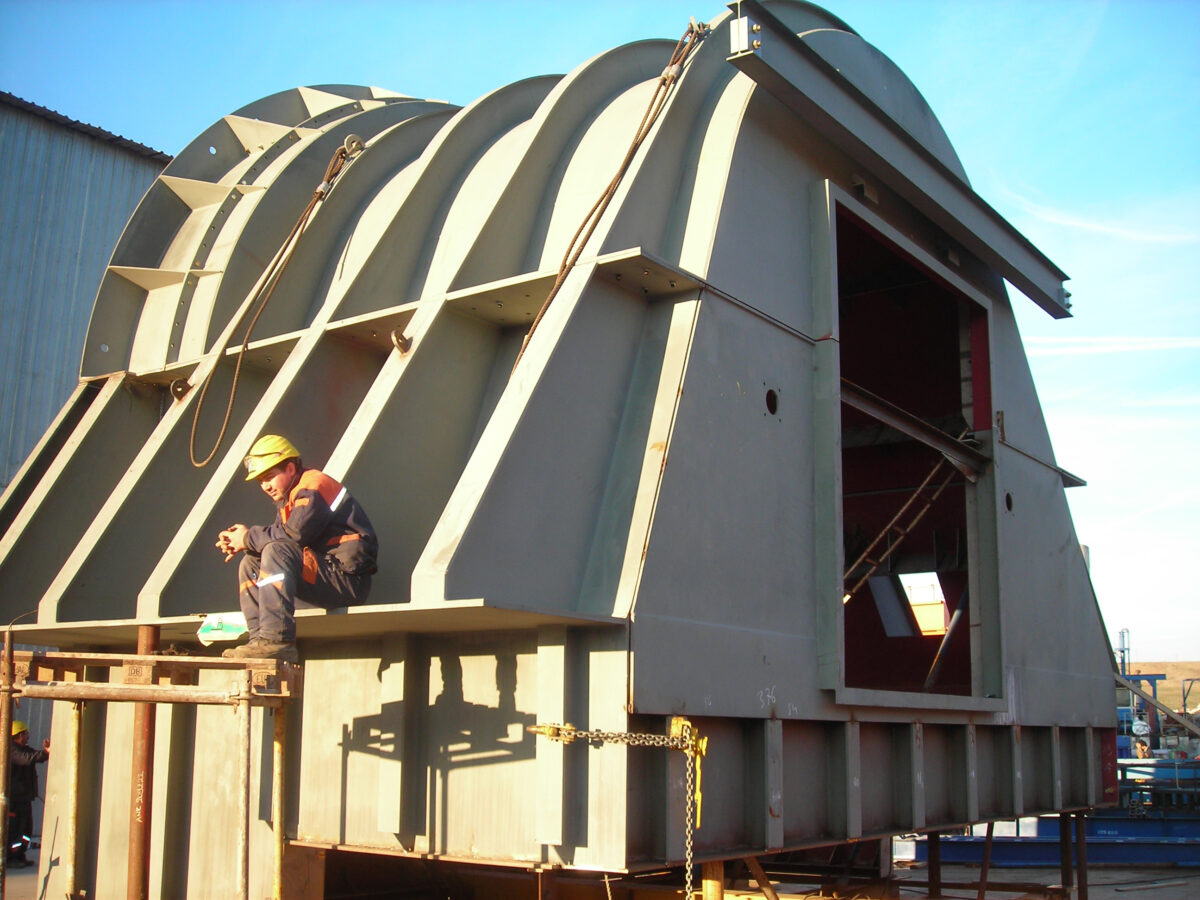

As QCTurk, we have achieved great success with the Coke Oven Machines project.

We made inspections for steel constructions, platforms and various type of machine structures for metallurgical facilities of a world known company. This project had remarkable tons of diverse type of steel work, heavy welded products, steel constructions and machinery systems also. Coke oven machines project executed by different suppliers in Turkey which are located in different cities by a bunch of QCTurk engineers. With this successful project, we have added value to the QCTurk brand.

You can check out the rest of our article to learn more about the details of the project.

We realized every detail of the project stages with our expert engineering knowledge. The whole processes were performed under our control from beginning to the end for this wide-ranging project. To clarify about the steel processes; first stage was with the raw materials (mostly steel plates controls) for us and their 3.1 material certificate. After procurement done by suppliers’ technical personnel, it continued with checking of the conformity of the material and the storage conditions, and followingly pre-manufacturing steps performed by the supplier including cutting, beveling and/or machining. When it comes the welding stage, it had strict control steps before, during and after the process completed. Before welding, entire preparations for welding were checked by us (e.g., beveling angles measurement, conformity conditions and any kind of nondestructive test if needed). The dimensional measurement before welding was crucial step to follow and if the steel parts are totally proper and acceptable for the welding, welding process started with an approval. During welding stages, certified welders of the suppliers had to be under control and coordinated regularly and neatly according to the international standards and specifications or directives. Welding was executed under the restrictions of PQR/WPS parameters all the process along. Followingly, after welding stage controls were ready to start by us with dimensional measurement of the parts. Due to the fact that, the assembly stage is essential for this kind of steel constructions/works and machine systems in particular, it was executed by the suppliers with care and after assembly measurements all system disassembled to ready for checks after. NDT controls or also known as nondestructive tests namely, Ultrasonic Test, Radiographic Test, Magnetic and Penetrant Tests were performed by the experts so the constructions or the parts getting ready for coating stages. Blasting is vital stage for painting systems which already organized by a suitable specification, so all the inspections in these stages had life sustaining importance during inspections. Labelling and marking controls were came after to get the parts ready for delivery and to finalize the inspections logistics stage controls/inspections were performed to approve the conformity afterwards.

All these inspection stages executed have been completely under our control and also recorded by us with reports, photos and videos. As well as the technical controls of the workload for this project, we did process monitoring to have the required values for expediting and reporting regularly with proper report format as like we do for quality control steps weekly or even daily basis.

The complete inspections, reporting and project supervision stages completed successfully by QCTurk’s experienced team members who are already professionals of this industry in Turkey and known largely.

You can follow our website and social media accounts to be informed about our other successful projects.